The property we purchased has an existing concrete foundation in the back. While it seems to be thick enough to build on, it isn’t raised above grade level at all so water accumulates. It also has some cracks that obviously go all the way through it, so we’ve determined that we’re better off not relying on it too much.

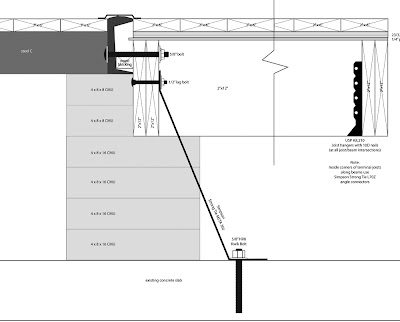

I want to have a sizable crawl space under the building for infrastructure access in the future. In addition to getting above any sub-Noah floodwaters, the height might even help keep out some of the critters. The engineer’s plan is to use simple concrete blocks to get the altitude needed.

You’d be surprised how much work those simple blocks turn out to be.

First, we have to get them home from Home Depot. Their rent-a-truck has a weight limit (with a really loud, irritating alarm), so it takes three runs back and forth to get them all home. Loading at the store, unloading at home, block by block on a hot, humid, Houston day.

I’m all excited when we first get them — happy to be doing something other than dragging a container across our yard — and we lay them all out where they need to go. After they’re all nicely stacked in their places we realize that — duh — the containers need to be placed into position first. The nice neat piles of blocks are in the way.

We (actually by this point, it’s “I”) move them out of the way. The next day I use the Egyptian method to move the containers into place. The next work day I jack up one end, place blocks, drop the jack. Jack the other end, place blocks, drop the jack. Back to the first end, put the jack on blocks, raise the container again, add another layer of blocks, drop the jack. Back and forth until the container is resting on blocks two feet up.

The next week, our engineer comes to do a site visit and notices that the “C” channel beams that go around the base of the container are broken up by the holes for forklifts. The piles of blocks that aren’t in the corners need to be divided up so that both ends of every segment of that C-channel is supported.

A few days later, we realize that the 2″ x 12″ wood members that make up the beams and joists need to sit lower than the containers:

So we unstack all of the piles and restack them, breaking some of the blocks in half. This creates a “step” for the wood to rest on, while still providing the height necessary for the container to sit on.

Fortunately the engineer had specified dry-stacking the blocks, so moving them many times iss just painful and time-consuming. If we had done cast concrete footings in place, life would now be hell.

A month later, when we we’re positioning the third and fourth containers, we have a big forklift. While this makes it much faster and easier to get the containers into the vicinity of where they need to be, it doesn’t help at all with getting the containers to sit perfectly parallel to, and the right distance from, its neighbors.